Why PTFE Coatings

Provides excellent non-stick characteristics, reducing friction and preventing adhesion.

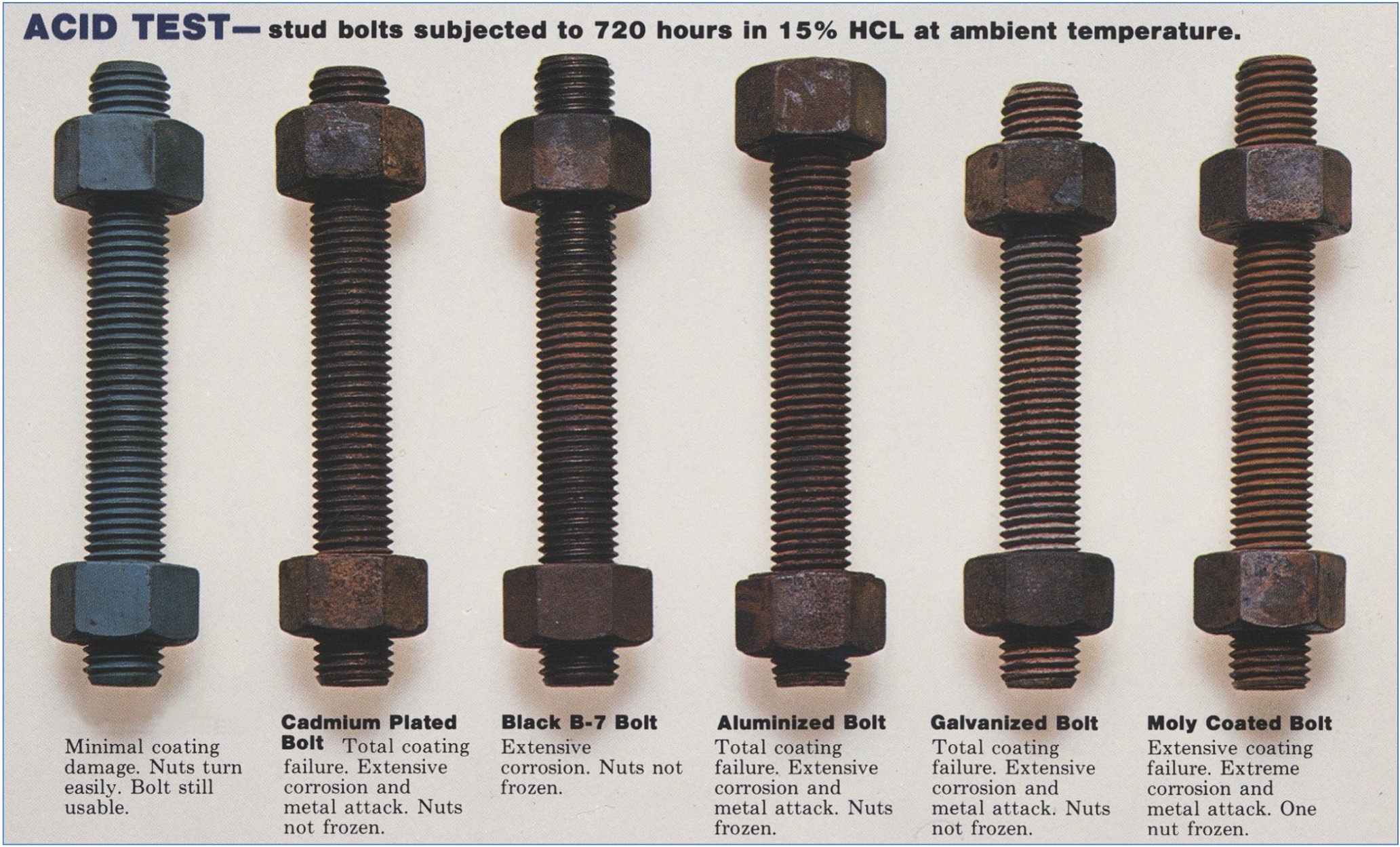

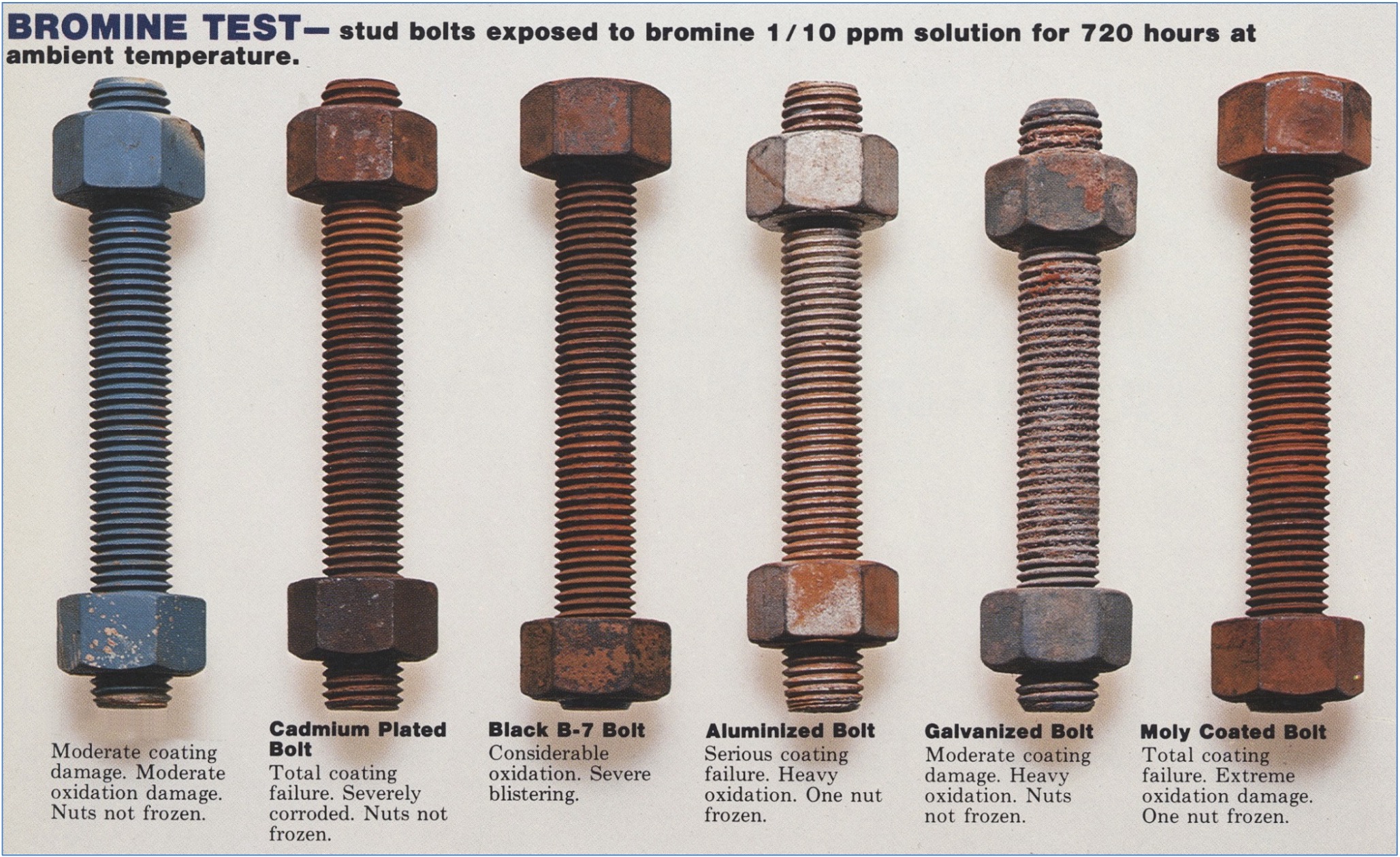

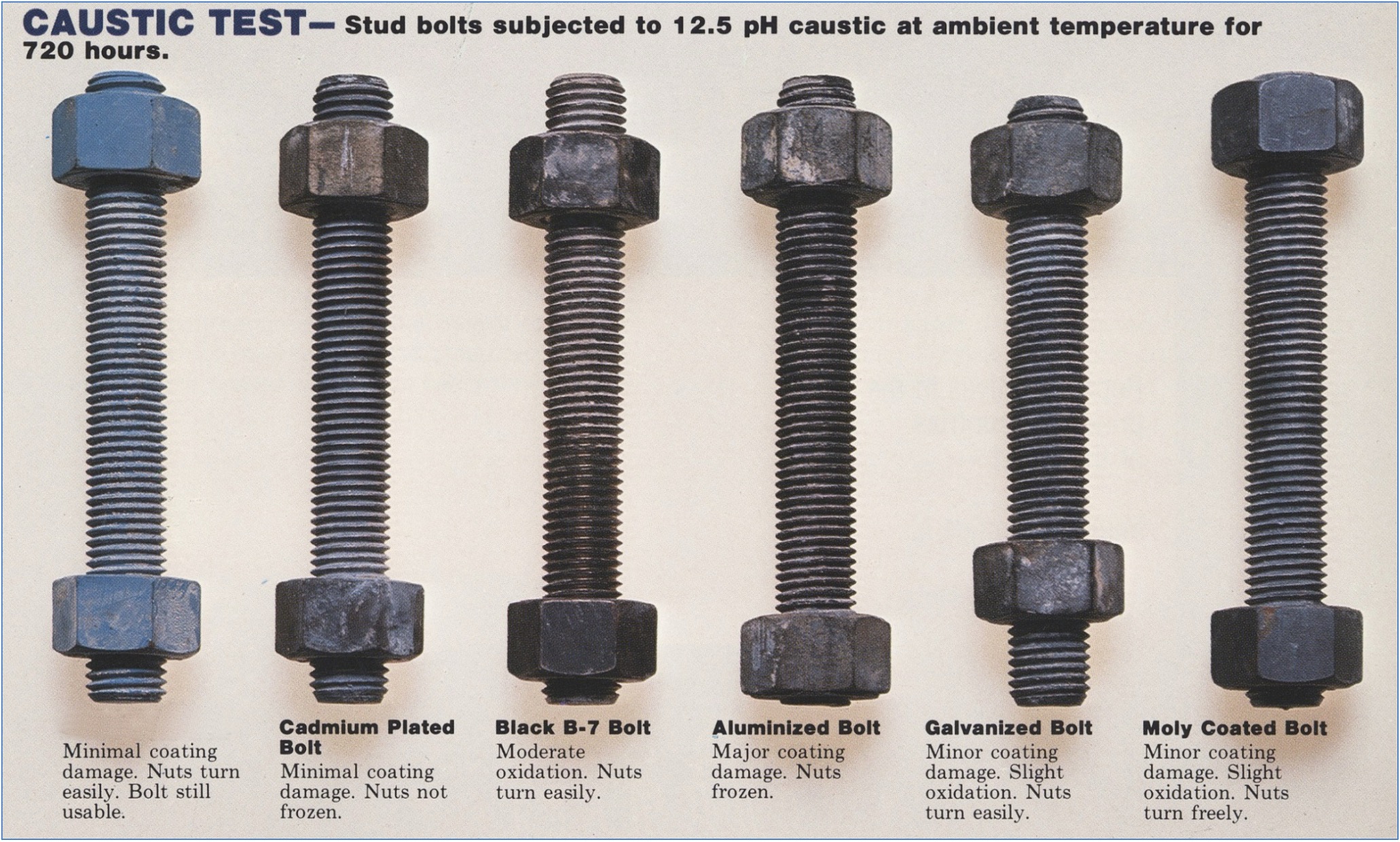

Offers resistance to a wide range of chemicals, acids, and solvents.

Reduces friction and wear on moving parts, improving efficiency and extending component life.

Maintains performance and integrity at elevated temperatures.

Protects against corrosion and oxidation, extending the lifespan of treated parts.

Repels water and moisture, preventing corrosion and promoting easy cleaning.

Benefits of PTFE Coatings

Types of PTFE Coatings

- Superior corrosion resistance

- Excellent chemical resistance

- High temperature tolerance

- Low coefficient of friction (non-stick)

- Enhanced wear resistance

The Science Behind XYLAN 1070

The magic of XYLAN 1070 lies in its unique formulation and application process. PTFE, known for its inertness and low friction, is combined with other high-performance resins and additives to create a robust coating. The application typically involves a multi-layer process, including surface preparation, primer application, and multiple coats of the XYLAN 1070 finish, followed by a high-temperature curing process to ensure optimal bonding and performance.

Technical Specifications (Typical Values)

| Property | Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | -195 to +260 | °C |

| Coefficient of Friction | 0.05 – 0.12 | – |

| Chemical Resistance | Excellent to most acids, alkalis, and solvents | – |

| Corrosion Resistance | High | – |

| Film Thickness | Varies based on application | µm |

Key Benefits of XYLAN 1070 Coating

- Extends the lifespan of components by protecting against wear and tear.

- Non-stick properties minimize cleaning and maintenance requirements.

- Low friction reduces operating forces and energy consumption.

- Protects against harsh chemicals, ensuring reliability in demanding environments.

- Safeguards against rust and corrosion, even in extreme conditions.

- Maintains performance at elevated temperatures, ensuring consistent operation.

Applications of XYLAN 1070

XYLAN 1070’s versatility makes it suitable for a wide range of industries and applications:

- Fasteners: Bolts, screws, and nuts for corrosion resistance and ease of assembly.

- Valves and Pumps: For chemical resistance and reduced friction.

- Pipes and Fittings: For protection against corrosive fluids.

- Molds and Dies: For non-stick properties and ease of release.

- Food Processing Equipment: For hygiene and easy cleaning.

- Automotive Components: For wear and corrosion resistance.

Application Process and Best Practices

- Surface Preparation: Cleaning, degreasing, and blasting to create a suitable profile.

- Primer Application: Applying a specialized primer for enhanced adhesion.

- XYLAN 1070 Application: Spraying multiple thin coats to achieve the desired thickness.

- Curing: Baking at a high temperature to fully cure the coating.

- Quality Control: Inspecting the coating for thickness, adhesion, and appearance.

- Exceptional non-stick properties (very low coefficient of friction)

- Excellent release characteristics

- Good chemical resistance

- Moderate temperature resistance

- Typically a multi-coat system for optimal performance

The Science Behind XYLAN 1014

The superior non-stick performance of XYLAN 1014 stems from the inherent properties of PTFE, which has one of the lowest coefficients of friction of any solid material. This coating often involves a multi-layered application process, starting with careful substrate preparation, followed by a primer to enhance adhesion, and multiple topcoats of the specialized XYLAN 1014 formulation. A controlled high-temperature curing process is essential to ensure the coating achieves its desired properties and bonds effectively to the substrate.

Technical Specifications (Typical Values)

| Property | Typical Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | +260 | °C (varies by specific formulation) |

| Coefficient of Friction | 0.02 – 0.10 | – (highly dependent on load and speed) |

| Chemical Resistance | Good resistance to a wide range of chemicals, consult specific compatibility data | – |

| Wear Resistance | Moderate, suitable for applications with less severe abrasion | – (performance depends on test conditions) |

| Film Thickness | Varies based on application requirements | µm |

- Unrivaled Non-Stick Performance: Minimizes adhesion of various materials, facilitating easy release and reducing build-up.

- Excellent Release Properties: Ensures clean and effortless separation in molding, food processing, and other release-critical applications.

- Good Chemical Inertness: Resistant to attack from many corrosive substances, extending the lifespan of coated components.

- Reduced Maintenance and Cleaning: The non-stick surface minimizes material accumulation, leading to easier and less frequent cleaning.

- Improved Efficiency: Lower friction can reduce operating forces and improve the efficiency of moving parts.

Applications of XYLAN 1014

The exceptional non-stick and release properties of XYLAN 1014 make it ideal for a variety of applications, including:

- Bakeware and Food Molds: Ensuring easy release of baked goods and processed foods.

- Packaging Machinery: Preventing sticking of films and products on sealing jaws and guide rails.

- Heat Sealing Bars: Preventing adhesion of packaging materials to the sealing surfaces.

- Printing Rollers: Facilitating smooth ink transfer and preventing ink build-up.

- Textile Processing: Reducing fiber sticking on rollers and guides.

- Rubber and Plastic Molding: Enabling easy release of molded parts from the molds.

Application Process and Best Practices

Achieving the optimal non-stick and release performance of XYLAN 1014 requires a well-controlled application process:

- Meticulous Surface Preparation: Thorough cleaning, degreasing, and often a specific surface roughening process to promote adhesion.

- Primer Application: Application of a compatible primer to enhance the bond between the substrate and the PTFE topcoats.

- Multiple Thin Coat Application: Applying several thin, even layers of the XYLAN 1014 coating to achieve the desired film thickness and uniformity.

- Precise Curing Cycle: Following the manufacturer’s recommended time and temperature profile for curing to ensure the coating develops its optimal non-stick and release properties.

- Quality Control Checks: Inspecting the coated parts for proper film thickness, adhesion, and surface finish to guarantee performance.

- Good non-stick properties (low coefficient of friction)

- Enhanced wear and abrasion resistance compared to basic PTFE

- Good chemical resistance to a range of substances

- Moderate temperature resistance

- Often a multi-coat system for optimized performance

The Science Behind XYLAN 1052

XYLAN 1052 achieves its performance through a carefully engineered blend of PTFE with other high-performance polymers and reinforcing fillers. This combination enhances the inherent properties of PTFE, particularly its wear resistance and adhesion to the substrate. The typical application process involves meticulous surface preparation, application of primer and multiple topcoats of XYLAN 1052, followed by a controlled thermal curing process to ensure a durable and well-bonded coating.

Technical Specifications (Typical Values)

| Property | Typical Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | -195 to +260 | °C (varies by formulation) |

| Coefficient of Friction | 0.02 – 0.10 | – (varies with load and speed) |

| Chemical Resistance | Good resistance to many chemicals, consult specific chemical compatibility data | – |

| Wear Resistance | Improved over pure PTFE | – (performance depends on test method) |

| Film Thickness | Varies based on application requirements | µm |

Key Benefits of XYLAN 1052 Coating

- Improved Wear Resistance: Offers greater resistance to abrasion and wear compared to standard PTFE coatings, extending component life.

- Good Non-Stick Performance: Facilitates easy release of materials and reduces build-up, simplifying cleaning processes.

- Enhanced Durability: Provides a robust protective layer against operational stresses and environmental factors.

- Good Chemical Resistance: Protects components from damage caused by exposure to a variety of chemicals.

- Versatile Applications: Suitable for a broad range of industrial uses where a balance of properties is required.

- Controlled Friction: Offers a predictable and relatively low coefficient of friction for smooth operation.

Applications of XYLAN 1052

XYLAN 1052’s balanced properties make it a preferred choice in numerous applications, including:

- Bakeware and Cookware: Providing non-stick surfaces for easy food release and cleaning.

- Mechanical Components: Reducing friction and wear in bearings, bushings, and slides.

- Rollers and Guides: Facilitating smooth material movement in various industrial processes.

- Sealing Elements: Offering low friction and chemical resistance for reliable sealing.

- Textile Machinery: Preventing fiber build-up and ensuring smooth operation.

- Packaging Equipment: Reducing sticking and ensuring efficient material handling.

- Automotive Components: For wear and corrosion resistance.

Application Process and Best Practices

- Thorough Surface Preparation: Cleaning, degreasing, and often grit blasting to create an optimal surface profile for adhesion.

- Primer Application: Applying a specifically designed primer to enhance the bond between the substrate and the XYLAN 1052 topcoats.

- Multiple Topcoat Application: Applying several thin layers of XYLAN 1052 to achieve the desired film thickness and performance characteristics.

- Controlled Curing: Following the manufacturer’s recommended time and temperature curing cycle to ensure the coating fully cross-links and achieves its optimal properties.

- Quality Inspection: Verifying coating thickness, adhesion, and overall quality to ensure the application meets specifications.

- Excellent wear resistance under high loads

- Low coefficient of friction

- Good chemical resistance

- Moderate to high temperature resistance (depending on formulation)

- Multi-coat system typically involving a binder and wear-resistant topcoats

The Science Behind XYLAN 1424

XYLAN 1424 achieves its unique combination of properties through a sophisticated blend of PTFE, reinforcing fillers, and high-performance binders. These components work synergistically to create a coating that can withstand significant mechanical stress while maintaining a low friction surface. The application process typically involves careful substrate preparation, followed by the application of a binder coat for enhanced adhesion and one or more topcoats containing wear-resistant additives within the PTFE matrix. A precise thermal curing process is essential to ensure the coating layers bond effectively and achieve their optimal mechanical and tribological properties.

Technical Specifications (Typical Values)

| Property | Typical Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | -20 to +175 | °C (varies significantly by specific formulation) |

| Coefficient of Friction | 0.05 – 0.09 | – (highly dependent on load, speed, and mating surface) |

| Wear Resistance | Excellent under high loads, significantly superior to standard PTFE | – (performance depends heavily on test conditions and mating material) |

| Chemical Resistance | Good resistance to many industrial chemicals, consult specific compatibility data | – |

| Film Thickness | Varies based on application requirements and load conditions | µm |

Key Benefits of XYLAN 1424 Coating

- Superior High Load Wear Resistance: Extends the service life of components subjected to significant contact pressures and movement.

- Very Low Coefficient of Friction: Reduces frictional forces, minimizing energy consumption and heat generation in moving parts.

- Enhanced Durability in Mechanical Applications: Provides a robust protective layer against wear, abrasion, and galling.

- Good Chemical Resistance: Protects components from degradation in various chemical environments.

- Reduced Noise and Vibration: The low friction surface can contribute to quieter and smoother operation of machinery.

Applications of XYLAN 1424

The exceptional wear resistance and low friction characteristics of XYLAN 1424 make it an excellent choice for demanding mechanical applications, including:

- Bearings and Bushings: Providing low friction and high wear resistance for extended service life.

- Gears and Splines: Reducing friction and wear in power transmission systems.

- Slides and Ways: Ensuring smooth and accurate linear motion under load.

- Threaded Fasteners: Facilitating controlled torque and preventing galling, especially in high-stress applications.

- Piston Skirts: Reducing friction and wear between the piston and cylinder wall.

- Automotive Components: Used in various parts requiring durability and low friction.

Application Process and Best Practices

Achieving the high-performance characteristics of XYLAN 1424 requires a precise and controlled application process:

- Rigorous Surface Preparation: Thorough cleaning, degreasing, and typically a specific grit blasting process to create an optimal anchor profile for the binder coat.

- Binder Coat Application: Applying a specially formulated binder to ensure strong adhesion to the substrate and provide a foundation for the wear-resistant topcoats.

- Wear-Resistant Topcoat Application: Applying one or more layers of the XYLAN 1424 topcoat, ensuring uniform thickness and proper distribution of wear-resistant fillers.

- Critical Curing Cycle: Adhering strictly to the manufacturer’s recommended time and temperature curing profile to achieve the desired hardness, wear resistance, and bonding between layers.

- Stringent Quality Control: Verifying coating thickness, adhesion strength, and surface finish to ensure the application meets the demanding performance requirements.

- Excellent dry lubrication (very low coefficient of friction)

- Outstanding wear and abrasion resistance, even under high loads

- Good chemical resistance

- Moderate to high temperature resistance (formulation dependent)

- Typically a multi-coat system with a robust binder and wear-resistant topcoats

The Science Behind XYLAN 1425

XYLAN 1425 achieves its remarkable performance through a carefully optimized formulation combining PTFE with advanced reinforcing fillers and high-performance resin binders. These components work in concert to create a durable coating with a very low coefficient of friction and exceptional resistance to wear. The application process involves meticulous surface preparation, application of a strong bonding primer, and multiple topcoats of the XYLAN 1425 finish, followed by a precisely controlled thermal curing cycle. This ensures the coating adheres strongly to the substrate and the individual layers are fully integrated, maximizing its tribological properties.

Technical Specifications (Typical Values)

| Property | Typical Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | -20 to +175 | °C (varies significantly based on the specific formulation) |

| Coefficient of Friction | 0.02 – 0.10 | – (highly dependent on load, speed, and mating surface conditions) |

| Wear Resistance | Exceptional under high loads and sliding conditions, significantly better than standard PTFE | – (performance is highly dependent on test parameters and mating material) |

| Chemical Resistance | Good resistance to a broad range of chemicals, refer to specific chemical compatibility data | – |

| Film Thickness | Varies according to application requirements and the severity of the operating environment | µm |

Key Benefits of XYLAN 1425 Coating

- Exceptional Dry Lubrication: Provides a very low coefficient of friction, reducing energy consumption and preventing stick-slip.

- Superior Wear and Abrasion Resistance: Extends the lifespan of components operating under high loads and in abrasive environments.

- Eliminates or Reduces the Need for Wet Lubricants: Offers a clean, dry lubrication solution, preventing contamination and simplifying maintenance.

- Enhanced Durability and Reliability: Provides long-lasting protection against wear, corrosion, and chemical attack.

- Improved Efficiency and Performance: Reduces friction, leading to smoother operation and increased efficiency of mechanical systems.

Applications of XYLAN 1425

The outstanding dry lubrication and wear resistance of XYLAN 1425 make it ideal for critical applications across various industries, including:

- High-Load Bearings: Providing long-lasting, low-friction performance under significant loads.

- Sliding Surfaces: Reducing friction and wear in linear motion systems and guides.

- Bushings and Sleeves: Offering dry lubrication and wear resistance in rotating and oscillating mechanisms.

- Automotive Wear Parts: Coating components like piston skirts, seals, and linkages for enhanced durability and reduced friction.

- Aerospace Components: Used in applications requiring reliable dry lubrication and wear resistance in demanding conditions.

- Industrial Machinery: Coating components in various machines to improve efficiency and reduce maintenance.

Application Process and Best Practices

To achieve the exceptional performance characteristics of XYLAN 1425, a precise and controlled application process is essential:

- Stringent Surface Preparation: Thorough cleaning, degreasing, and a carefully controlled abrasive blasting process to create an optimal surface profile for maximum adhesion of the primer coat.

- High-Performance Primer Application: Applying a specialized primer designed to bond strongly to the substrate and provide a robust foundation for the wear-resistant topcoats.

- Multiple Wear-Resistant Topcoat Application: Applying several thin, uniform layers of the XYLAN 1425 coating to achieve the specified film thickness and ensure even distribution of the lubricating and wear-resistant particles.

- Precise Thermal Curing Cycle: Adhering strictly to the manufacturer’s recommended time and temperature curing schedule to ensure full cross-linking of the coating and development of its optimal mechanical and tribological properties.

- Comprehensive Quality Control: Conducting thorough inspections of the coated parts, including film thickness measurements, adhesion testing, and surface finish analysis, to guarantee the application meets the stringent performance requirements.

- Excellent resistance to a wide range of corrosive environments

- Low coefficient of friction for lubricity

- Good wear resistance

- Broad operating temperature range

- Typically a multi-coat system for optimal performance

The Science Behind XYLAR 2F1197

XYLAR 2F1197 achieves its unique combination of properties through a carefully selected blend of fluoropolymers, corrosion inhibitors, and lubricating pigments within a robust resin matrix. The multi-layer application process is crucial, typically involving thorough surface preparation, application of a primer with corrosion-inhibiting properties, and one or more topcoats that provide both the low friction surface and further barrier protection against corrosion. A controlled thermal curing process ensures the coating layers are properly bonded and the system achieves its intended performance characteristics.

Technical Specifications (Typical Values – Always Consult the Manufacturer’s Data Sheet)

| Property | Typical Value | Unit |

|---|---|---|

| Temperature Resistance (Continuous) | -40 to +535 | °C (range can vary based on specific conditions) |

| Coefficient of Friction | 0.11 – 0.13 | – (dependent on load, speed, and mating surface) |

| Corrosion Resistance | Excellent resistance to salt spray, humidity, and many chemicals | – (performance varies with exposure duration and environment) |

| Wear Resistance | Good, suitable for applications with moderate wear demands | – (performance depends on load and sliding distance) |

| Film Thickness | Varies based on application and performance requirements | µm |

Key Benefits of XYLAR 2F1197 Coating

- Superior Corrosion Protection: Provides a robust barrier against rust, oxidation, and chemical attack, extending component life in harsh environments.

- Integral Lubricity: Offers a low coefficient of friction, reducing wear, preventing galling and seizing, and ensuring smooth operation.

- Wide Operating Temperature Range: Maintains its protective and lubricating properties across a broad spectrum of temperatures.

- Enhanced Durability: The multi-layer system provides a tough and adherent coating that withstands operational stresses.

- Reduced Maintenance Costs: The combination of corrosion resistance and lubricity can lead to longer service intervals and reduced maintenance.

Applications of XYLAR 2F1197

XYLAR 2F1197’s unique combination of corrosion resistance and lubricity makes it ideal for a wide array of applications, including:

- Fasteners and Bolting: Preventing corrosion and ensuring ease of assembly and disassembly, even after exposure to harsh conditions.

- Valve Components: Providing corrosion resistance and lubricity for smooth operation and extended life in various media.

- Offshore and Marine Applications: Protecting against saltwater corrosion and reducing friction in moving parts.

- Automotive Chassis and Components: Offering corrosion protection and lubricity for critical parts exposed to road salts and environmental factors.

- Chemical Processing Equipment: Resisting attack from a wide range of chemicals while providing lubricity for moving parts.

- Power Generation: Protecting components from corrosion in demanding environments and ensuring reliable operation of moving parts.

Application Process and Best Practices

To achieve the optimal performance of XYLAR 2F1197, a carefully controlled application process is crucial:

- Thorough Surface Preparation: Cleaning, degreasing, and typically abrasive blasting to achieve the specified surface profile for optimal primer adhesion.

- Application of Corrosion-Inhibiting Primer: Applying a primer specifically formulated to provide excellent adhesion and active corrosion protection to the substrate.

- Application of XYLAR 2F1197 Topcoat(s): Applying one or more uniform layers of the XYLAR 2F1197 coating to achieve the desired film thickness and provide both lubricity and a barrier against corrosion.

- Controlled Thermal Curing: Following the manufacturer’s recommended time and temperature curing cycle to ensure proper cross-linking of the coating system and development of its protective and lubricating properties.

- Rigorous Quality Control: Inspecting the coated components for film thickness, adhesion, corrosion resistance (through testing), and coefficient of friction to ensure performance specifications are met.