Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of metal parts, typically aluminum, to improve durability, corrosion resistance, and aesthetic appeal. During anodizing, the metal part is submerged in an electrolyte solution and subjected to an electric current, which thickens and strengthens the oxide layer.

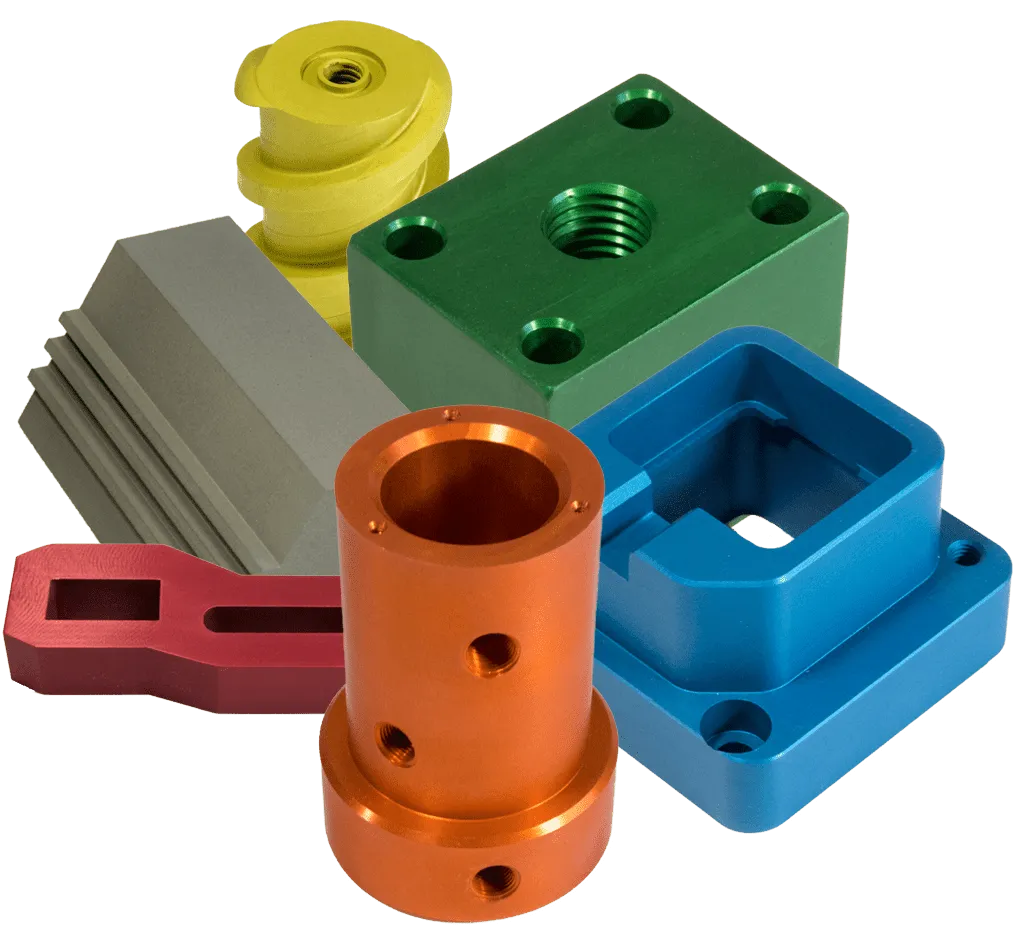

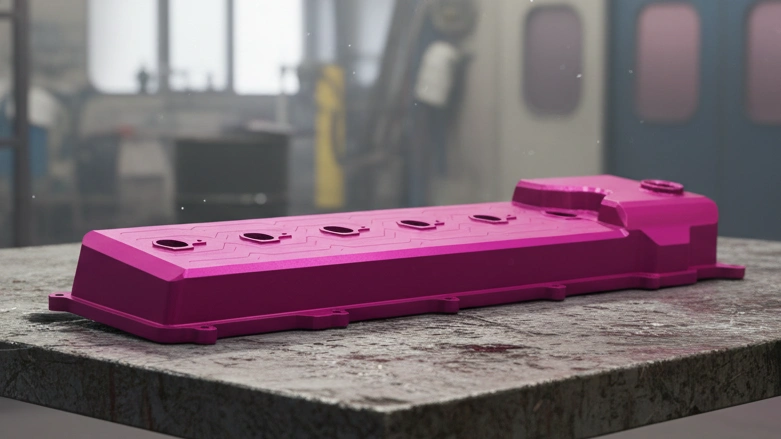

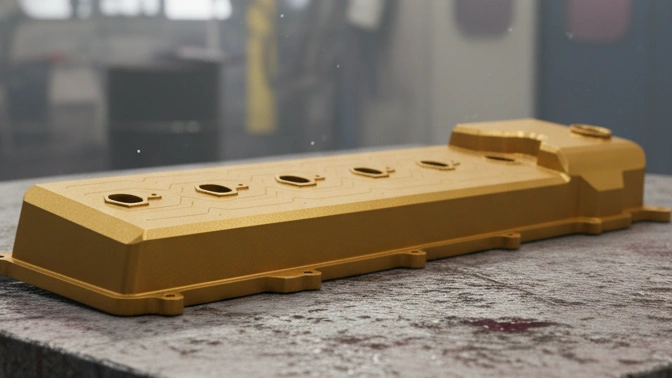

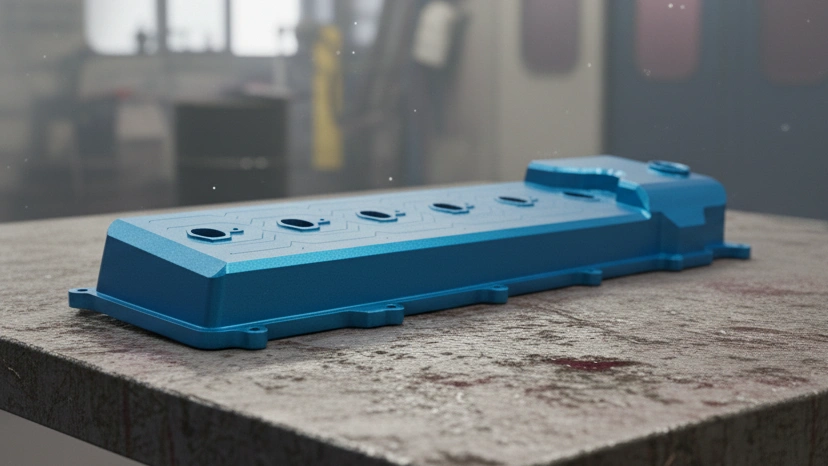

This process not only protects the metal from environmental factors but also allows for the application of vibrant, long-lasting colors through dyeing. Anodized coatings are integral in industries such as aerospace, automotive, and consumer electronics, where they provide superior wear resistance, reduce maintenance needs, and enhance the visual appearance of components.

Anodizing is an environmentally friendly process, as it does not involve harmful chemicals and produces a non-toxic, recyclable finish. We offer anodizing as per MIL-A-8625 TYP-II, IIB & III on Class -1 & 2, with extensive experience in catering to the stringent requirements of the aerospace, power generation, and oil and gas industries.