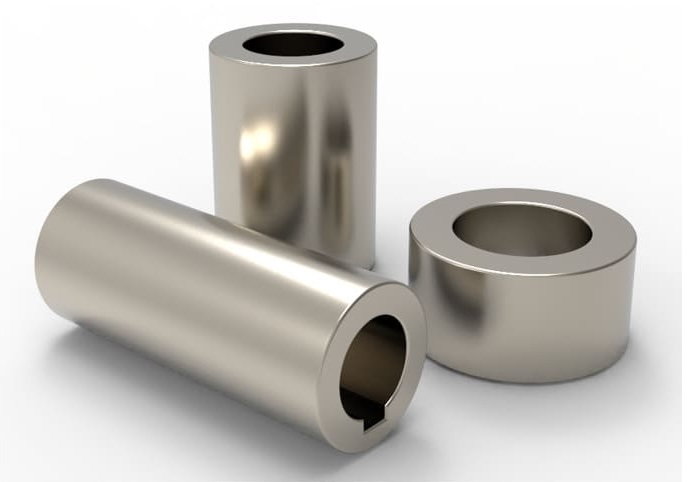

Electroless Nickel Plating (ENP) is an autocatalytic chemical process that deposits a uniform layer of nickel-phosphorus alloy onto a metal, including steel, aluminum, copper, and even non-metallic surfaces without the use of an electric current. This technique offers exceptional corrosion resistance, enhanced hardness, and improved wear resistance, making it ideal for a wide range of industrial applications.

The uniformity of the coating is one of ENP’s most significant advantages, ensuring consistent coverage on complex geometries and intricate parts where traditional electroplating might fail. Additionally, ENP provides excellent adhesion and can be applied to a variety of materials, including steel, aluminum, copper, and even non-metallic surfaces.

This versatility, combined with its ability to provide a smooth, aesthetically pleasing finish, makes Electroless Nickel Plating a preferred choice in industries such as aerospace, automotive, and electronics. It is also a critical solution in the oil and gas, petrochemical, and power generation industries, where components are constantly exposed to harsh, corrosive environments and require reliable, high-performance protection to ensure operational safety and longevity.